Products

Our equipment is custom designed and built based on the customer's specifications. In cases where there is a lack of equipment specifications, Main Flame will provide various ideas for customer consideration. Each project begins with a conceptual layout submitted for approval prior to manufacturing. Our equipment can be supplied in a turnkey, partial installation, or direct supply for customer install.

Sample Furnaces & Ovens

Electrically heated, annealing ovens for automotive lamps.

| |

Electrically heated, annealing ovens for automotive lamps with a cooling zone.

| |

Gas and electric aluminum melters and holders.

| |

Gas fired slot forge furnaces.

| |

Direct and indirect gas fired hot stamp furnaces.

| |

Gas and electric annealing ovens for the aerospace industry.

| |

Gas fired paint burn-off ovens.

| |

Existing furnace additions and retro-fits.

| |

Single and multi zone walking beam furnaces.

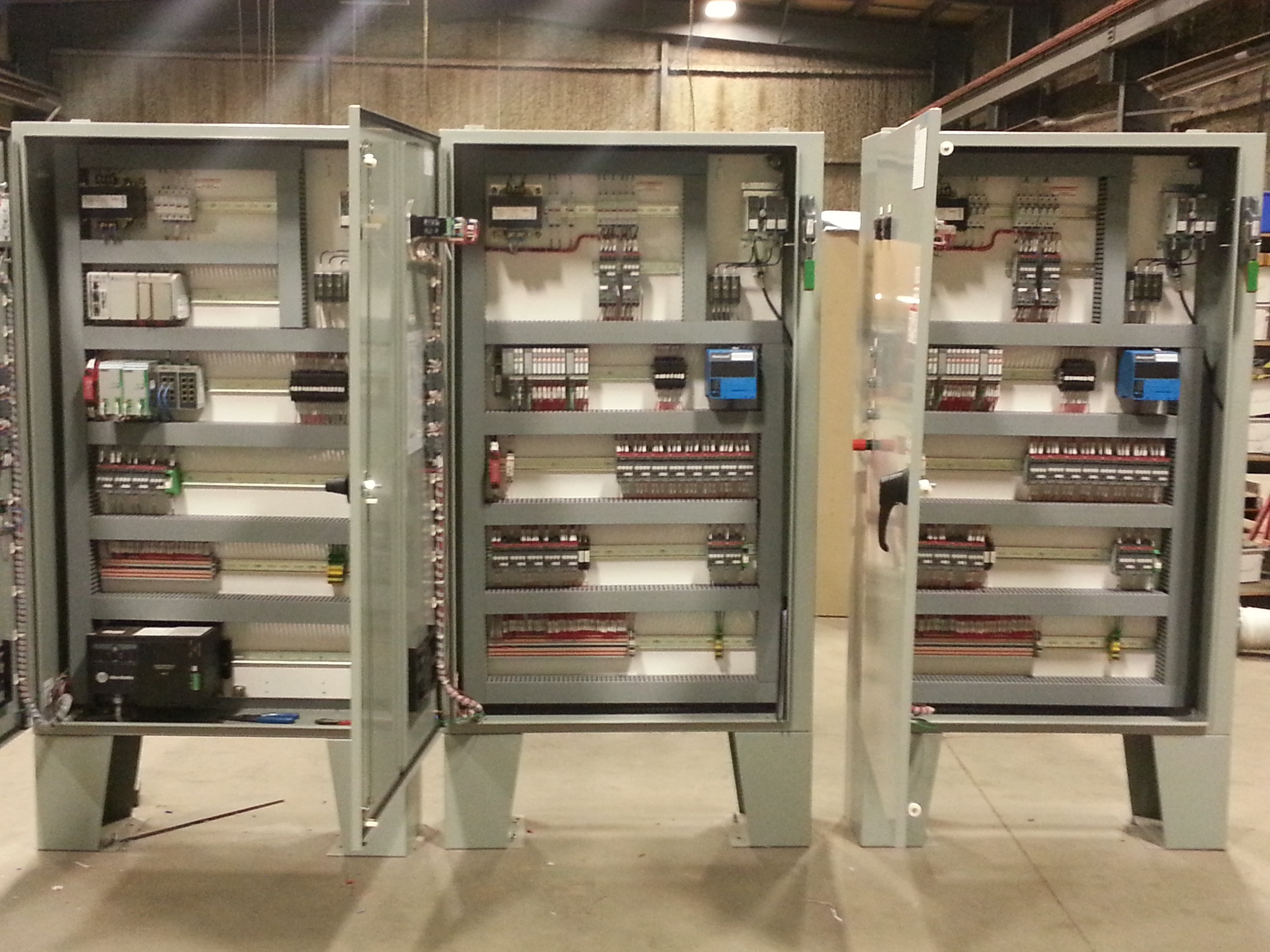

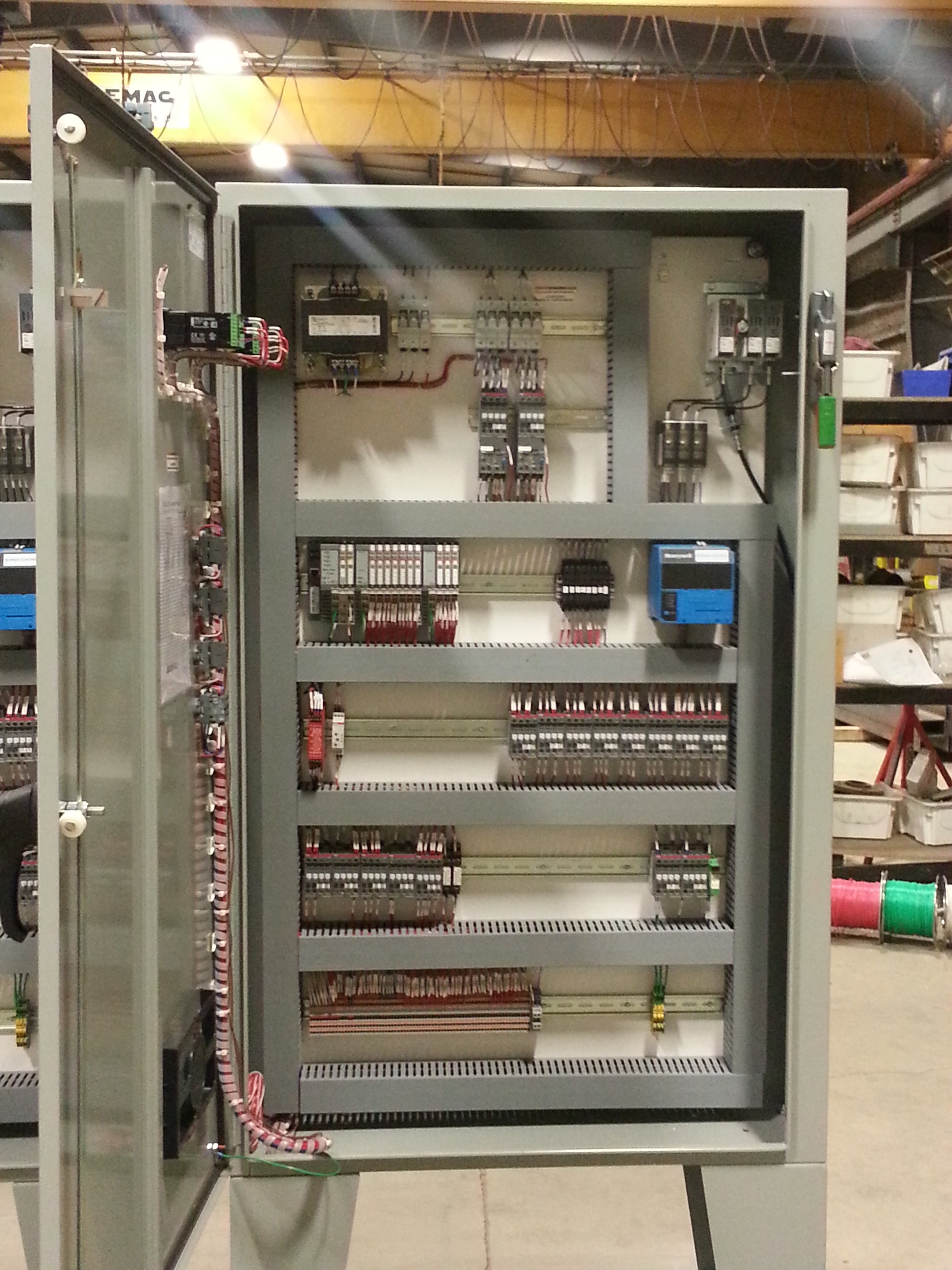

Control Panels

Simplistic relay form with stand alone temperature controllers, pilot lights & push buttons.

PLC/HMI form with automatic start-up & shut-down sequencing, equipment overview screens, operator assisted instructions, I/O status, temperature trending, password protected maintenance screens and other optional screens as requested.

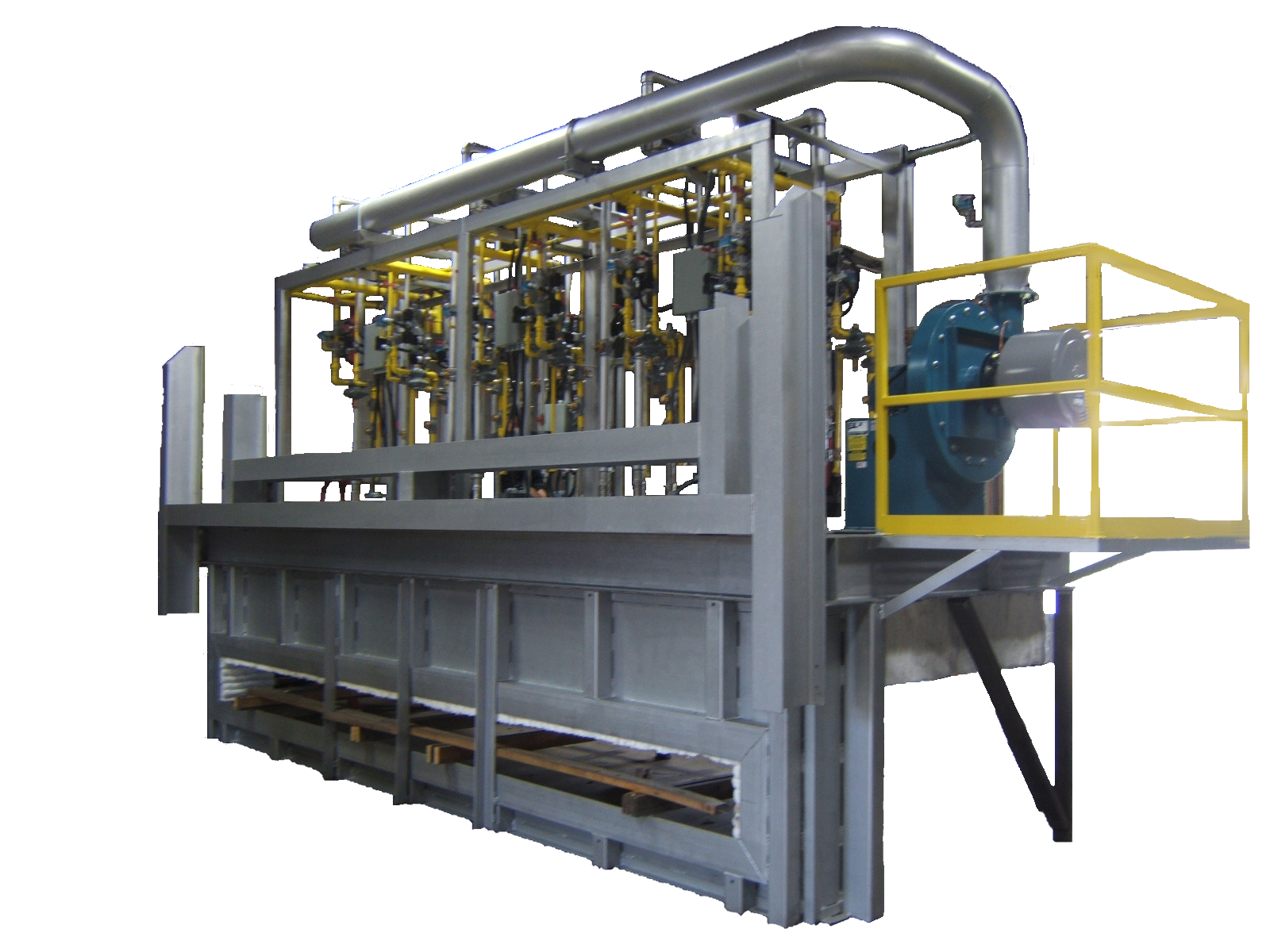

Gas Trains

Our gas trains are designed & built with the following in mind:

Correct flow rates & pressures for all burner input sizes.

Ease of maintenance for adjustment and replacement of components.

Per local gas code requirements.